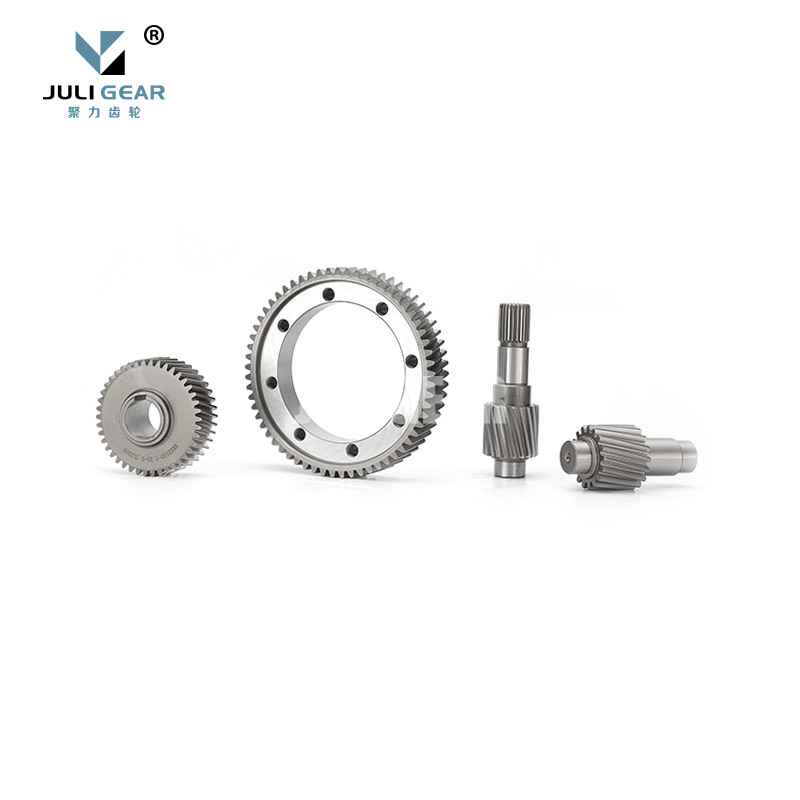

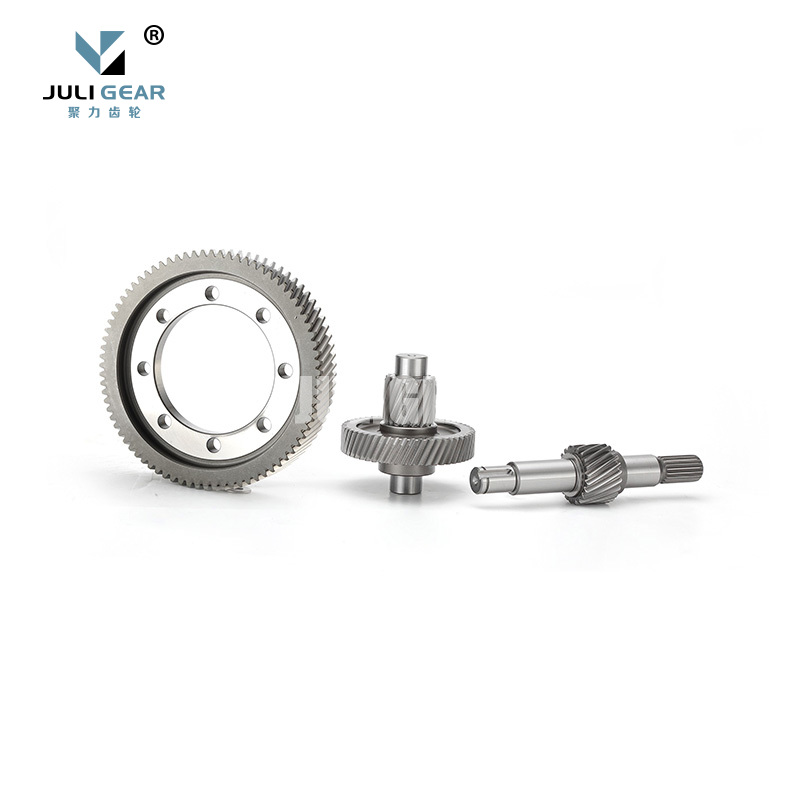

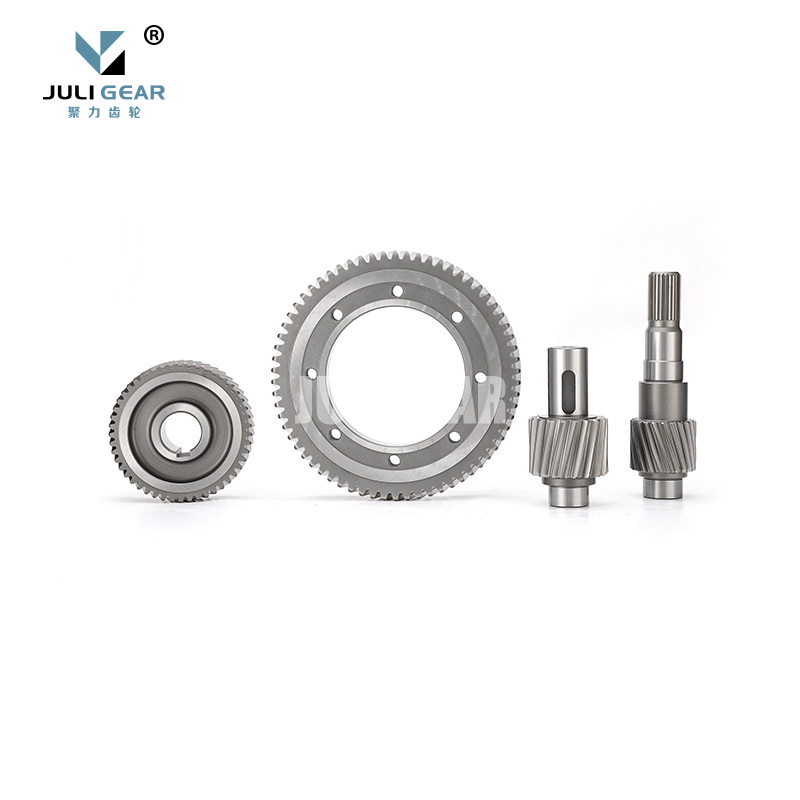

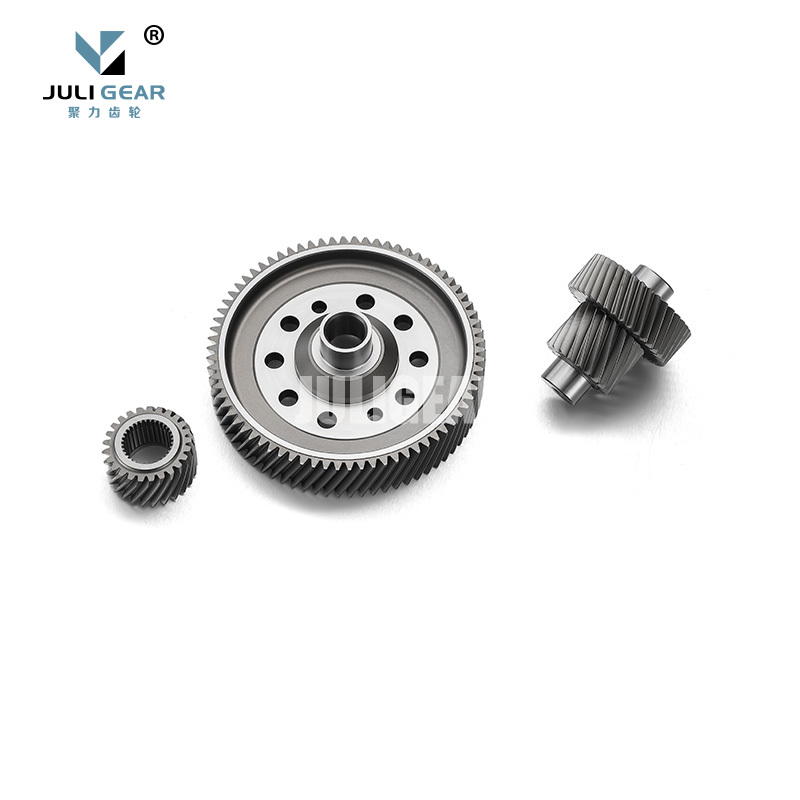

At JULI, we take pride in our commitment to engineering excellence and precision manufacturing. Our high-precision transmission cylindrical spur gears are a testament to our dedication to producing mechanical components that power various industries and applications. With a focus on quality, reliability, and performance, our gear products are trusted by customers worldwide.

High Precision

Our product lineup primarily consists of high-precision cylindrical gears, with a modulus ranging from 0.5 to 8. What sets our gear apart is the high level of accuracy we offer. In mass production, we achieve accuracy levels up to 4, ensuring that our gears meet even the demanding requirements of modern machinery and equipment.

Key Features:

Wide Modulus Range: Our cylindrical spur gears cover a modulus range from 0.5 to 8, catering to a broad spectrum of applications.

High Precision: Our gears are manufactured with meticulous attention to detail, achieving precision levels up to 4, which is crucial for applications requiring tight tolerances.

Reliability: JULI gears are known for their reliability, ensuring smooth and dependable power transmission in various mechanical systems.

Customization: We understand that every application is unique. Therefore, we offer customization options to meet your specific gear requirements.

Diverse Applications: Our gears find applications in industries such as automotive, aerospace, robotics, industrial automation, and many others.

Precision at its Core

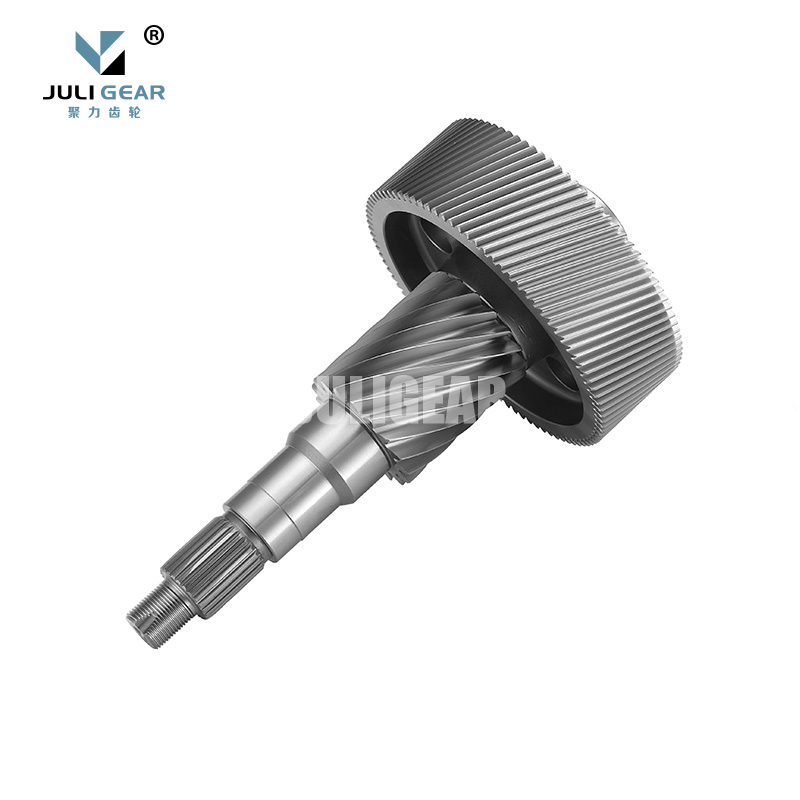

Our high-precision transmission cylindrical spur gears are the result of advanced engineering and manufacturing practices. Here are the core aspects that make our gears stand out:

1. Advanced Materials: We utilize high-quality materials to ensure durability and performance in demanding conditions. The choice of materials is tailored to the specific requirements of the application.

2. Advanced Machinery: Our manufacturing facilities are equipped with advanced CNC machinery, gear hobbing machines, and inspection tools that allow us to consistently produce gears with high accuracy.

3. Quality Control: Quality is paramount at JULI. Rigorous quality control processes are in place at every stage of production to ensure that each gear meets our stringent standards.

4. Skilled Workforce: Our team comprises highly skilled engineers and technicians who are experts in gear manufacturing. Their expertise and dedication are reflected in the quality of our products.

Custom Solutions

We understand that one size does not fit all. Hence, we offer customization options to meet your specific gear needs. Whether you require gears with unique specifications, materials, or coatings, our team will work closely with you to create tailored solutions that ly match your application requirements.

Applications

JULI's high-precision transmission cylindrical spur gears have found their place in a wide range of applications, including:

Automotive: Our gears are used in transmissions, differential systems, and power steering systems, contributing to the performance and efficiency of vehicles.

Aerospace: In the aerospace industry, precision and reliability are paramount. JULI gears are trusted in various aircraft systems, from landing gear to flight control.

Robotics: Precision gears are crucial for robotic movements. Our gears enable robots to perform intricate tasks with accuracy and consistency.

Industrial Automation: In manufacturing and industrial automation, our gears are used in conveyor systems, CNC machines, and other machinery that keeps production lines running smoothly.

Global Reach, Local Support

JULI has a global presence, and our products are trusted by customers across the world. We provide comprehensive customer support, including technical assistance and after-sales service, to ensure the seamless integration of our gears into your applications.

JULI's high-precision transmission cylindrical spur gears represent a commitment to excellence and precision engineering. When you choose JULI, you're choosing quality, reliability, and performance that goes beyond expectations. Contact us to discuss how our gears can power your innovation and drive your success.

English

English русский

русский