- Technical Parameters

- ENTERPRISE STRENGTH

- Any Question

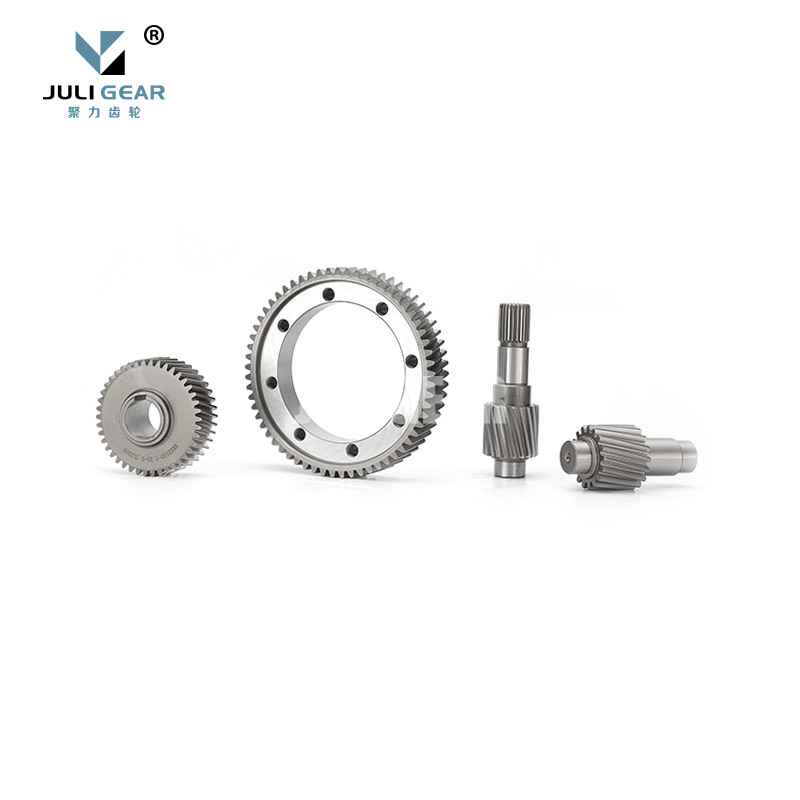

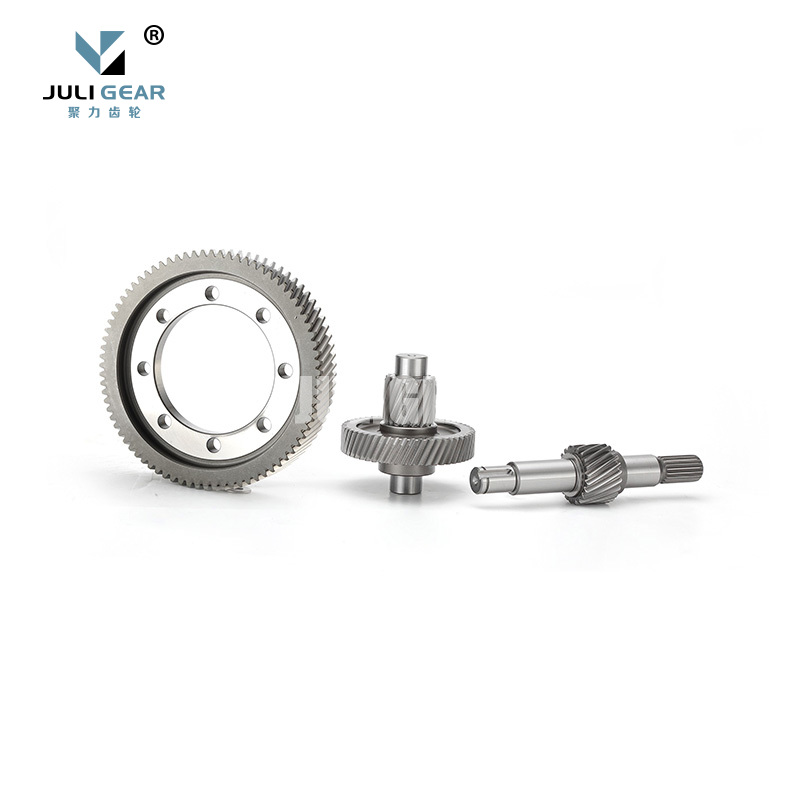

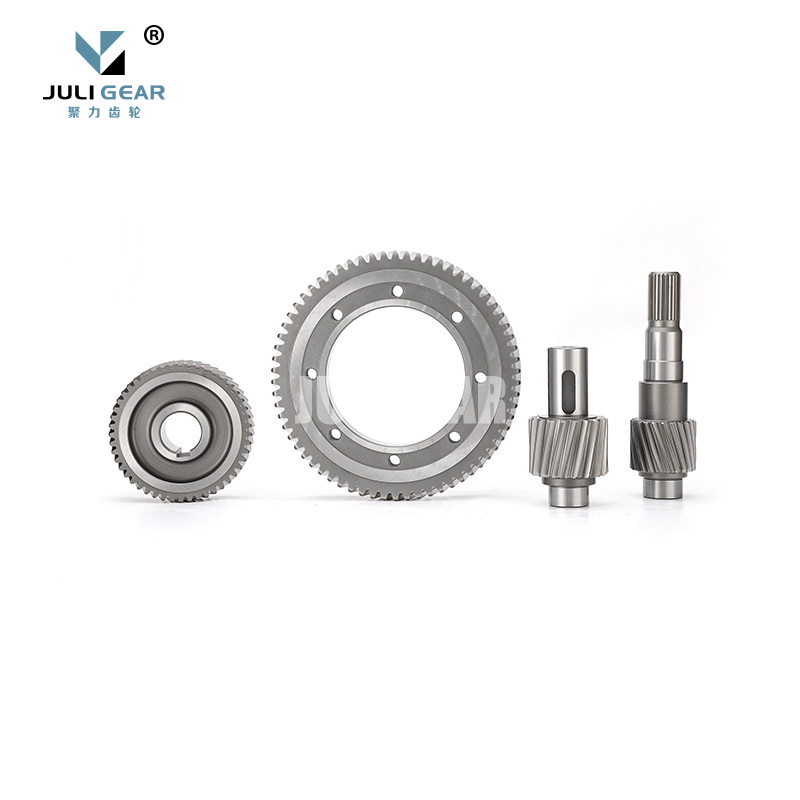

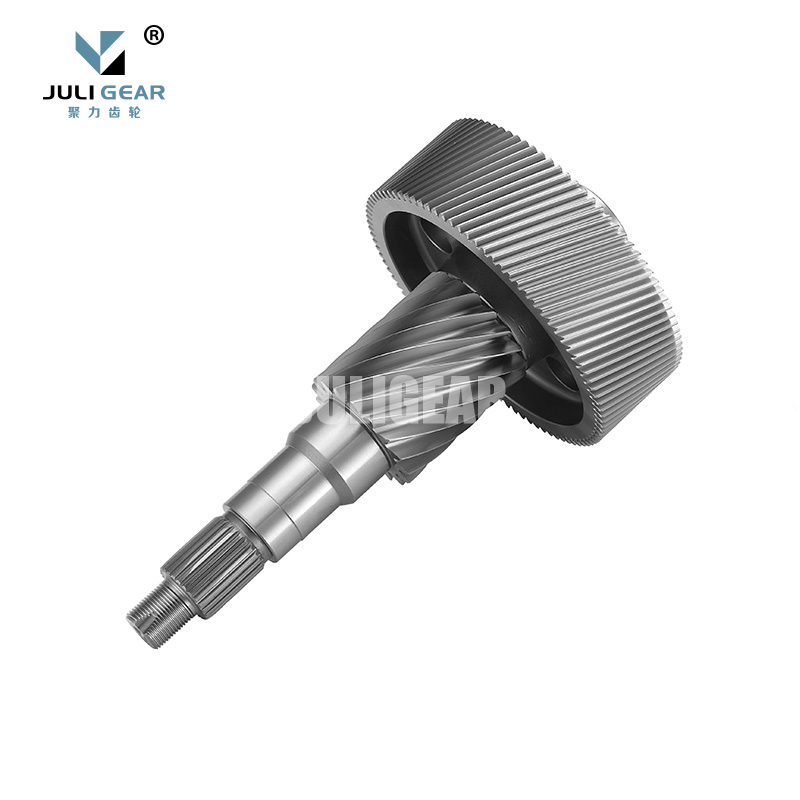

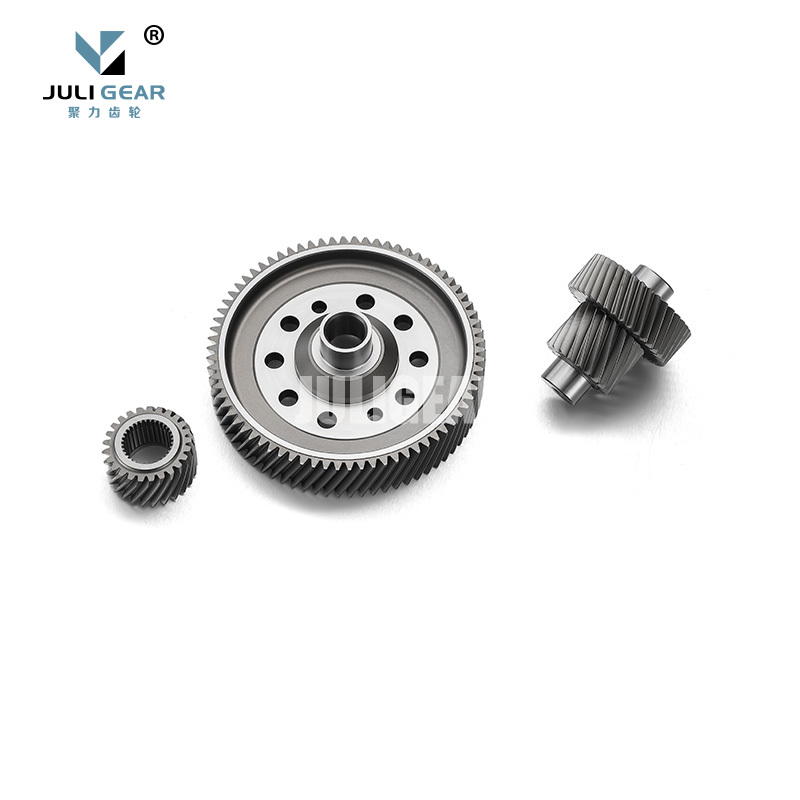

| Type | Spur/helical gear |

| Precision grade | ISO Level 5 |

|

Practice requirements for tooth shape |

Crowning |

| ffa cumulative error | 8um |

| Tooth surface requirement | Grinding Gear |

| Hardness requirement | HRC58-62 |

| Pressure Angle | Can be customized upon request |

| Material | Alloy steel |

| Heat treatment method | Carburizing |

|

Processing range |

Diameter within 500mm |

About Wenling Juli Gear Co., Ltd.

Wenling Juli Gear Co., Ltd. is a precision transmission gear manufacturer with the ability to research, manufacture, and sell.

Our company mainly produces new energy vehicle gear, reducer gear and precision planetary reducer gear, engineering machinery gear, power tool gear, transmission gear, precision machine tool equipment gear, precision oil pump gear, and other high-precision transmission gear.

Our products are widely used in the new energy automobile industry, reducer industry, construction machinery industry, precision machine tool equipment industry, printing machinery, spinning machinery, military machinery, and other fields.

We mainly produce 4-6 level high precision cylindrical gear, the accuracy can reach to DIN4 precision (ffa cumulative error can be within 2μm).

We survive by quality and based on cultivating core competitiveness, we have passed ISO9001:2015 and quality management system authority certification of automotive industry standard IATF16949:2016.

Our company is a national high-tech enterprise in Zhejiang Province, and we obtained more than 10 items of gear patent certificates of honor. The company has a metrology testing system and testing equipment. Also, we have a strong ability in precision measurement, physical and chemical detection, and metallographic analysis.

Our company has a strong R & D team. According to the demand of customers, we can provide a complete set of gear designs, full customization service of researching, testing samples, and mass production.

Juli has several sets of horizontal seven-axis high-efficiency hobbing machines, vertical seven-axis high-efficiency hobbing machines, high-efficiency gear grinding machines, double-station high-efficiency gear grinding machines, gear machines, and other high-end advanced equipment.

Over the years, the company has adhered to the principles of innovation-oriented, quality-for-survival, and core components that drive the world to serve the world.

Company mission: Gather all efforts, drive the world, and serve the world.

Company products: According to customer need, we customized produce 0.5-8 modules of new energy vehicle gear, transmission gear, engineering machinery gear, precision reducer gear, precision machine tool equipment gear, and other high-precision transmission gear.

Certificates We Have Obtained

Our Blog

English

English русский

русский